Do you ever find yourself daydreaming about how much simpler life would be if only you could thread a bobbin on your sewing machine? Of course, the answer is probably no! but believe it or not, understanding what a bobbin is can actually make all of your sewing dreams come true! So sit back and relax as we explore the fascinating world of bobbins.

Have you ever been to one of those traditional quilting parties where everyone gathers around the host’s giant industrial-sized sewing machine? As they gush over its many features, have you found yourself wondering “What is that little metal cylinder thingy at the bottom?” If so, then congratulations –you have just stumbled onto the secrets behind bobbins.

A bobbin may seem like an insignificant part of a sewing machine, but in reality, this small metal cylinder plays an important role in helping create beautiful garments and craft projects. Read on to learn what is a bobbin on a sewing machine and how it can transform any project from ordinary to extraordinary!

Related Topic: What is a “Hook Race” on a Sewing Machine: Sewing Machine Mystery

Table of Contents

ToggleWhat is a Bobbin on a Sewing Machine?

A bobbin is a small object that has many uses in sewing, but what does it really do? From plastic bobbins to metal ones, each type of bobbin plays an essential role when it comes to creating stitches. Let’s take a closer look at the mysterious world of bobbins and find out why they are so important for sewing projects.

The most basic function of a bobbin is winding thread around it. This creates tension on one side while keeping the other side free from strands. The wound bobbin can then be placed in the appropriate area of the machine and threaded with its counterpart above it. Once everything is set up correctly, the two threads will intertwine as they pass over and under each other, producing neat stitching patterns every time.

In addition to providing support for efficient stitching, bobbins also help maintain fabric structure by preventing excessive fraying or shrinking during use. By placing a lightweight yet durable plastic or metal bobbin underneath your material before you start stitching, you ensure that all parts remain securely held together even after repeated needle punctures. Threaded bobbins provide extra protection against wear and tear too – no matter how hard you work your materials!

Bobbins may seem insignificant but their importance should never be underestimated – without them our creations would be far less beautiful! They provide us with reliable support during any crafting experience, ensuring we get maximum results every time we stitch something special together.

Benefits Of A Bobbin

The bobbin plays an important role in the sewing process. It holds the lower thread that is used to stitch together two pieces of fabric. But its importance extends beyond this task; there are several benefits of having a bobbin on your sewing machine.

One advantage is a bobbin winder, which allows you to quickly and easily fill bobbins with thread. This makes it easier to start new projects without wasting time winding multiple spools of thread onto separate bobbins one at a time. Additionally, different styles of bobbins can be used for various tasks, such as free-motion quilting or embroidery designs.

Another benefit of bobbins is improved tension control when stitching. Bobbins come preloaded with thread already secured inside them, so they remain consistent while you sew. This helps eliminate issues like uneven stitches due to changes in tension caused by the unspooling of threads from individual spools.

Lastly, making sure your bobbin has enough thread before beginning a project ensures that you won’t run out mid-seam–saving yourself precious time and effort! Knowing how much thread each type of bobbin holds can help ensure that you’re always prepared for your next project.

With these advantages in mind, let’s look at what different bobbin sizes are available for use on modern sewing machines.

What Are The Different Bobbin Sizes?

When it comes to using a sewing machine, the bobbin is an essential component. Take for example Sue, who recently purchased her first-ever sewing machine and needed to know what type of bobbins she should use.

She knew that there were different sizes available but wasn’t sure which one was right for her project. In this section, we’ll look at the different types of bobbins you can get and how they are used with your spool of thread.

The most common bobbins are threaded or pre-wound bobbins. These come in either plastic or metal varieties and typically have a small hole in the center where you insert the thread from your spool.

Once inserted, you then wind the bobbin until full so it’s ready for use when stitching. Some machines also offer extra bobbins that fit around the main bobbin so you can switch out colors quickly as well as save time on winding multiple bobbins.

Finally, if you want to save money and hassle, some machines allow you to wind your own empty plastic or metal bobbin without having to buy extra ones each time – all you need is a bit of thread from your spool!

This process involves placing the empty bobbin onto the machine and slowly turning it while gently pushing down on the pedal to ensure even winding throughout. As long as you don’t overfill it, this method works great and allows you to easily keep backups handy when needed.

With these tips in mind, now let’s explore whether or not it’s possible to use a sewing machine without a bobbin.

Can You Use A Sewing Machine Without A Bobbin?

It’s impossible to overstate just how essential bobbins are to the functioning of a sewing machine. Without them, your projects will be halted in their tracks! So what happens if you don’t have one? Can you sew without a bobbin?

The answer is yes – but it requires some creative thinking and problem-solving on your part. You’ll need to understand the basics of how a bobbin works in order for this solution to work: Bobbins come in many shapes and sizes; from a regular round spool shape to drop-in bobbins or even ones with winder stoppers. A bobbin helps provide tension while winding thread onto the needle so that when you start stitching, everything runs smoothly.

At its most basic level, if you’re in a pinch and don’t have access to any type of metal or plastic bobbin, you can still make use of an empty spool or other makeshift devices (like cardboard).

To do this successfully, try wrapping some thread around the spool several times and then feeding it through the eye of the needle before beginning your project. It won’t be as reliable as using proper bobbins such as those wound by a bobbin winder, but it should get you up and running until more suitable supplies arrive!

So there we have it – although not ideal by any means, there are ways that allow us to keep working on our craft even if we’re temporarily missing out on vital components like bobbins!

Are Metal Bobbins Better Than Plastic?

When it comes to sewing with a machine, you need the right bobbin in order to get started. But when deciding which type of bobbin is best for your project, should you opt for metal or plastic?

To make an informed decision, let’s take a look at the pros and cons of both types:

- Metal bobbins are durable and can handle heavier fabrics, but they also tend to be more expensive than their plastic counterparts.

- Plastic bobbins come in many sizes that fit specific machines; however, some may not last as long as metal ones.

- Metal bobbins will typically require less threading since the needle won’t pull on the spool pin as much. On the other hand, plastic bobbins often have smoother surfaces which reduce friction while stitching.

- Lastly, if you frequently switch between projects using different fabric weights, then having both types of bobbins available could be beneficial.

Whether you choose metal or plastic depends on what kind of job needs doing and how much time/money you’re willing to invest.

It’s important to remember that either way–both types of bobbins provide the essential support needed for any successful sewing project! With this knowledge under your belt, we can now move on to exploring whether all bobbins fit in all sewing machines…

Do All Bobbins Fit In All Sewing Machines?

When it comes to sewing machines, one of the most important components is the bobbin. Sewing machines depend on a metal or plastic bobbin to store and dispense thread in order for the machine to work properly. But do all bobbins fit in all sewing machines? Here are three key points to consider:

Firstly, if you’re wondering whether your particular bobbin will fit into your machine, it’s best to check with the manufacturer or retailer as different models have different thread guides and foot pedals that may not be compatible with other types of bobbins.

If you’re looking for something portable, there are also special portable bobbin winders available that can help accommodate any type of bobbin size.

Secondly, when purchasing a new model of sewing machine make sure that it has an appropriate thread guide so that you can use your existing bobbins without having to purchase more from the same brand. It’s always worth double-checking before investing in a new unit just to make sure everything fits together correctly.

Finally, if you already own a sewing machine but need additional bobbins for specific projects then again it’s advisable to consult with the manufacturer or retailer about what kind of units they support. Without this information, it could mean extra expense down the line due to incompatible items being purchased unnecessarily.

It pays off to be aware of these factors when selecting and using bobbins in conjunction with your sewing machine! With this knowledge secured now let us move on to how we can successfully thread those pesky bobbins…

How To Thread A Bobbin In A Sewing Machine

It is a common theory that threading a bobbin on a sewing machine can be difficult. However, with the right instructions and supplies, this seemingly daunting task can be completed quickly and easily! Whether you are new to using a sewing machine or have been doing it for years, you’ll find these steps helpful in threading your bobbin correctly.

To begin, make sure your sewing needles are removed from the needle plate – this will help keep them safe while also making it easier to access the area where the bobbin goes.

Next, place the bobbin onto your machine’s spindle and press down firmly so that it stays securely in place. Then, get some thread – be sure to use one that matches your project – and cut off two tails approximately 6 inches long each.

Feed one tail through the small guide hole at the top of the bobbin case until it comes out again near its bottom edge. Now take both tails and wrap them around three times clockwise before pulling them snugly against the lower side of the slot they came out from earlier.

Afterward, start winding up the extra length of thread left over by turning either the hand wheel or balance wheel depending on what type of machine you own; continue winding until there’s just enough space between full wraps for about an inch or so more of additional thread (make sure not to wind too tightly).

Once done properly, secure any remaining threads together by tucking their ends underneath other loops already present on your bobbin spool. Lastly, remove all excess slack from the upper thread before inserting it into tension discs – this should ensure optimal stitching performance with correct tension applied throughout the entire fabric piece being worked on.

By now you should have successfully threaded your bobbin in preparation for whatever creative projects await!

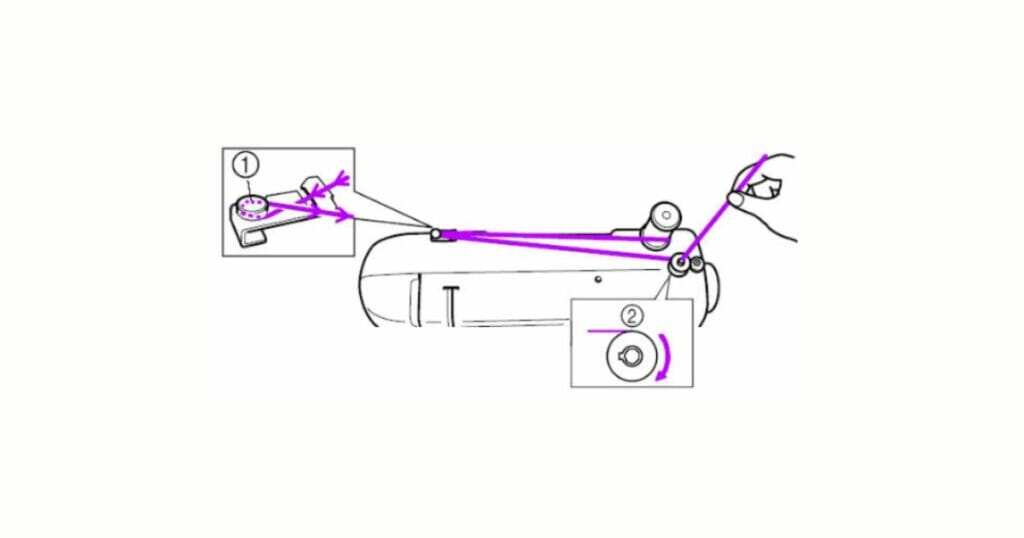

How To Wind A Bobbin

Learning how to wind a bobbin is an essential skill for any sewer. Take the case of Sarah, who had just bought her first sewing machine and was eager to make some simple garments. She quickly realized that she needed to learn how to wind a bobbin before making anything.

To help you get started with winding your own bobbins, here are four key steps:

- Ensure your thread tension is properly set on your lockstitch sewing machine by adjusting the dial located near the needle plate.

- Place the spool of thread onto the spool pin above the needle area.

- Insert an empty bobbin into the front-loading bobbin case, then place it beneath the presser foot.

- Follow the instructions given in your manual or online tutorial as each model may vary slightly when it comes time to actually start winding the fabric around your new bobbin.

With this knowledge, you will be able to create beautiful fabrics with ease! As long as you remember these 4 points, winding a bobbin can become second nature – allowing you to focus on creating stunning works of art out of material.

So don’t let learning how to wind a bobbin stop you from achieving greatness – take control and master this skill today! With that said, let’s move on to our next topic: inserting a bobbin into a sewing machine.

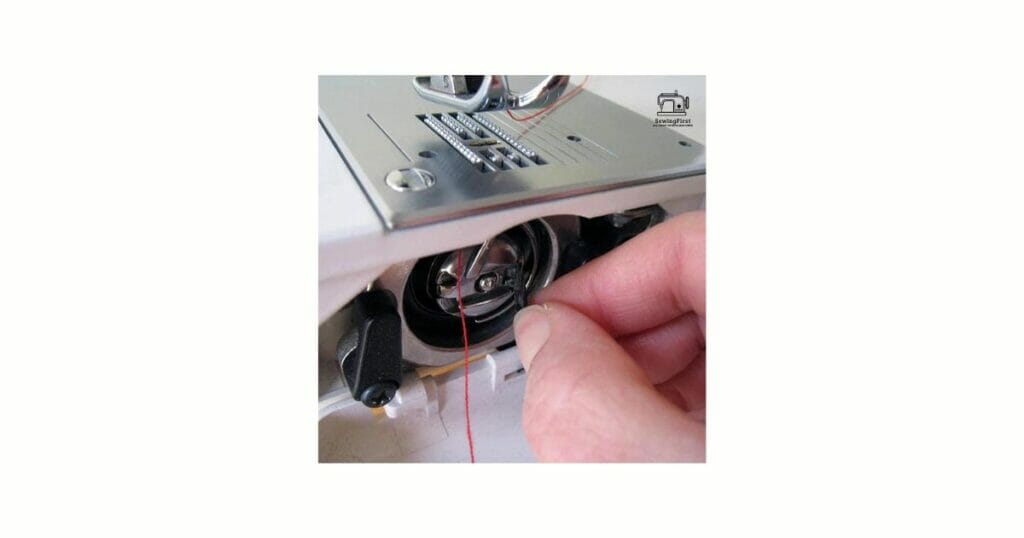

How To Insert A Bobbin

Did you know that over 72% of households in the US own at least one sewing machine? Inserting a bobbin is an essential part of any sewing project and can be easily done with just a few steps. Here’s how to do it:

- First, raise the presser foot on your sewing machine using the lever near the needle.

- Put your entire bobbin into the bobbin case. Make sure it is facing correctly by aligning the tension disks inside the case with those on the side of the bobbin itself.

- Slide or clip (depending on your model) the bobbin case onto its designated area following your machine’s instructions.

Next, pull out about 6 inches (15 cm) of thread from the top of your bobbin and place it behind the presser foot before passing it through both upper and lower tension discs for guidance.

Once all threads are passed through each disc, slowly turn your hand wheel clockwise until you see them appear at the needle plate’s eyelet hole. Afterward, cut off the excess thread at this point using scissors so as not to cause incorrect bobbin formation when stitching later on.

With these simple steps, you’re now ready to start any sewing project with confidence!

How a Bobbin Works in a Machine

Did you know that approximately one in every four sewing machines has an incorrect bobbin? Knowing how a bobbin works is essential for avoiding this problem.

A bobbin, which is a small spool of thread, plays a key role in the operation of a sewing machine. It sits at the bottom of the machine and holds extra thread while the needle comes down to stitch fabric together.

The main purpose of the bobbin is to provide tension to ensure that each stitch looks neat and even on both sides. Without it, stitches would not be formed correctly as they are pulled up by the needle from below.

In addition to providing tension, bobbins also contribute to controlling the speed of stitching. Bobbins come with different amounts of thread depending on their size; larger bobbins have more thread than smaller ones which can affect how quickly or slowly the needle moves across your fabric when you’re sewing. This makes sure that whatever project you’re working on turns out just right!

Having knowledge about these two crucial functions helps sewers avoid common problems like uneven stitches and inconsistent speeds – all things that could ruin any project if done incorrectly due to an incorrect bobbin! So now let’s find out what holds a bobbin in place…

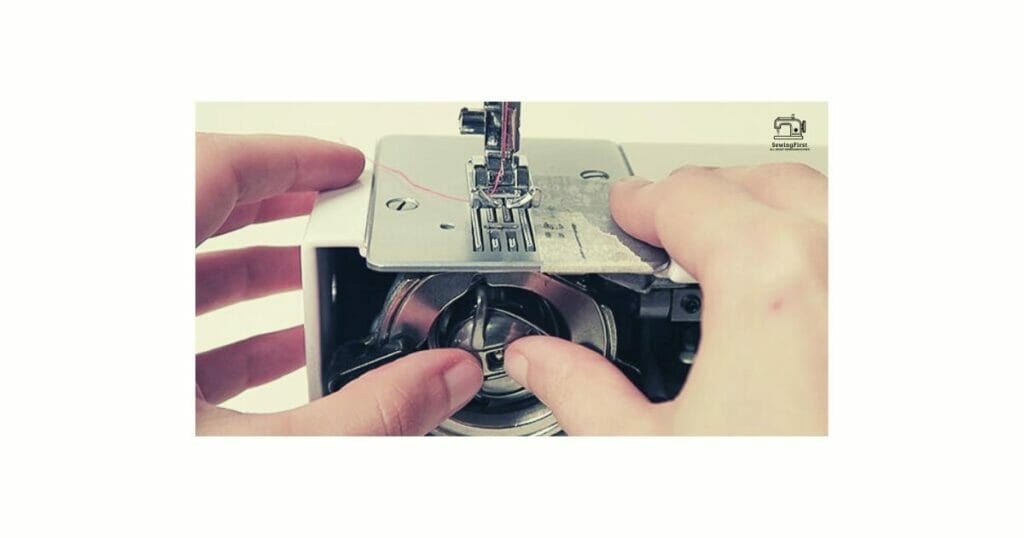

What Holds a Bobbin in Place?

The bobbin, a small spool of thread found in every sewing machine, is the unsung hero of garment construction. It may seem insignificant, but without it, there would be no way to stitch garments together. But what holds this vital component in place?

Securely nestled within the confines of the sewing machine’s inner workings lies the answer: a bobbin case. This piece of equipment acts as both an anchor and protector for your bobbin thread. The casing fits snugly into its designated area, ensuring that when you start stitching, it won’t slip or move around during operation.

Beyond just providing stability for the bobbin’s position, the case also serves to keep foreign objects from interfering with its spinning motion. Whether it’s dust bunnies or stray threads gathering inside the machinery, nothing can penetrate through and tangle up your work!

Without a secure holder like this one, these potentially dangerous elements could wreak havoc on any project you were working on – making bobbin cases invaluable pieces of protective gear.

Bobbins are integral components in successful clothing creations – but they need proper care and protection too! Thankfully, their trusty casings do an excellent job at keeping them safe while we sew away happily ever after.

Bobbin Thread Problems

The little metal cylinder tucked away inside the sewing machine—the bobbin. It’s a complex piece of engineering and when it goes wrong, all your hard work can unravel in moments!

Many sewers have experienced this moment of dread as they unpick stitch after stitch, trying to find out why their project isn’t working. But don’t worry; help is here. Let’s take a look at some common bobbin thread problems so you can get back to enjoying your creative projects.

One hurdle with bobbins is feeding them correctly through the tension discs within the sewing machine. If not done correctly, threads might become tangled or break off easily which will create an uneven stitch on your fabric.

To avoid this problem, make sure to feed the upper and lower threads into separate tension discs from both sides of the disc simultaneously. This prevents any knots from forming between each thread and keeps everything running smoothly.

Another issue that occurs occasionally is misaligned stitches due to one side being pulled more tightly than another by the bobbin thread. This often happens if there’s too much pressure on either side during stitching as well as incorrect tension settings for your particular needle size and fabric weight combination.

A helpful tip is to check these settings before starting a new project, or even in between seams while stitching, to ensure optimal results every time!

By following these simple steps above and taking care of how you feed, adjust and manage your bobbin thread, you’ll be able to avoid common issues and keep crafting beautiful creations without interruption! On we go then; let’s now explore troubleshooting techniques for those times when things do go awry…

Troubleshooting Bobbin Problems

Sewing machines are a wonderful tool when it comes to creating clothes, accessories, and other items. But if you ever run into problems with the bobbin thread, things can quickly become frustrating. Fortunately, troubleshooting bobbin problems is not as difficult as some people may think.

To begin with, check that your machine has been threaded properly. This includes following the manufacturer’s instructions for winding the bobbin by placing it on the winder tension disk and stopper at its base.

Next, ensure that there is enough pressure on both threads so they don’t slip out of their guides while sewing. Finally, make sure the upper and lower tensions are set correctly – this should be indicated in your user manual or online resources from the company that made your machine.

If none of these steps solve your problem then consider taking apart the machine to see if any parts need replacing or cleaning before putting it back together again.

Don’t forget to test it afterward to make sure everything works well! With a bit of patience and trial-and-error you can easily get through most bobbin issues without too much hassle – leaving you free to focus on all those beautiful creations you have planned!

Bobbin Winder Tension Disk And Stopper

The bobbin winder tension disk and stopper represent balance. They work together to create a safe, secure sewing experience while allowing for creativity and exploration. Just like two sides of the same coin, they are both essential parts of any successful project.

The bobbin winder tension disk and stopper help keep your stitches even by controlling the speed at which the thread is wound onto the bobbin. Here are some tips on how you can use them:

- Check that your needle plate is correctly adjusted before winding bobbins.

- Make sure that the thread is properly threaded through the tension guide.

- Set the correct tensions based on what type of fabric you’re using.

- Adjust the tightness or looseness of your threads as needed with either knob.

- Clean around these parts regularly to prevent jamming or damage from dust buildup.

Without these two components working in tandem, it would be impossible to produce consistent results across multiple projects—a necessity for anyone who takes their craft seriously!

Taking care when adjusting each component allows users to ensure accuracy, precision, and quality every time they sit down at their machine. All this serves as a reminder that attention to detail will always bring success; no matter what level of expertise you have achieved in sewing, proper maintenance yields results far beyond expectations.

Sewing Machine Bobbin Problems And Solutions

It’s no secret that a bobbin is an essential component of any sewing machine. But what happens when this crucial part becomes faulty or wears out? In that case, it can be difficult to figure out the best solution for your problem. Fortunately, there are some strategies you can use to diagnose and fix bobbin issues with your sewing machine.

The first step in resolving a bobbin issue is understanding the source of the problem. For example, if you’ve recently changed the thread on your spool, it may have caused tension problems;

similarly, if you’re using an incompatible bobbin size or type, it could lead to jamming and other malfunctions. Identifying these potential causes can help you determine which solutions will work best for restoring proper function to your machine.

Once you’ve determined the cause of the issue, there are several techniques that can help get things back up and running again. You might need to adjust the tension disk or stopper on your bobbin winder before replacing any parts – doing so could make all the difference between success and failure!

Additionally, cleaning debris from around the hook area – where threads cross over each other – is another great way to keep things humming along smoothly without having to replace anything at all.

No matter how complex your particular situation might seem, one thing remains true: with patience and knowledge about what’s going wrong inside your sewing machine, almost every problem has a viable solution waiting just around the corner!

Conclusion

In conclusion, a bobbin is an essential part of any sewing machine. It holds the lower thread to create strong stitches and keeps the fabric in place. Without it, no matter how good your machine is, you won’t be able to sew properly or get the desired result from your projects.

It’s also important to make sure that my bobbin tension is correct at all times so that my threads don’t end up creating lumps or tangles while I’m trying to sew something.

To do this, I’ll need to pay attention to both the bobbin winder tension disk and stopper settings when setting up my machine each time before use. With these tips in mind, I should have no problem getting professional-looking results every time!

FAQs

What is the difference between a bobbin and a spool?

A bobbin is a cylindrical spindle used to hold thread, ribbon, or yarn. It is typically made of plastic or metal and is used in sewing machines and hand sewing. A spool is a cylindrical object that is used to store thread, ribbon, or yarn. It is typically made of wood or plastic and is used to dispense the material.

What does a bobbin look like?

A bobbin is a small spool of thread or other material. It is usually cylindrical in shape and made of plastic or metal. The bobbin is used on sewing machines, looms, and other machinery that requires winding of thread or yarn.

What is another name for bobbin?

Bobbin can also be referred to as a spool.

How many bobbins do you need?

This depends on the project you are working on. If you are working on a loom, you will need to calculate the number of bobbins required based on the size and complexity of your project.

What are bobbins very short answer?

Bobbins are spools used to hold thread or other materials used in sewing and weaving.

What happens if you run out of bobbin thread?

If you run out of bobbin thread while sewing, the thread will break and the needle will stop moving. You will need to replace the bobbin thread with a new one before continuing with your project.

Why do I need to thread a bobbin?

Threading a bobbin is necessary because it supplies the lower thread to the sewing machine needle. The bobbin thread is what forms the stitches on the underside of the fabric and provides support to the stitches on the top side. Without a correctly threaded bobbin, the stitches will be loose and the fabric may not hold together properly.

How many types of bobbins are there?

There are three main types of bobbins: hand-wound, shuttle, and pre-wound. Hand-wound bobbins are wound by hand and are used with manual sewing machines. Shuttle bobbins are used in shuttle-style sewing machines. Pre-wound bobbins are ready-to-use bobbins filled with a spool of thread.

What does a bobbin look like?

A bobbin is a small spool of thread or other material. It is usually cylindrical in shape and made of plastic or metal. The bobbin is used on sewing machines, looms, and other machinery that requires winding of thread or yarn.

What is another name for bobbin?

Bobbin can also be referred to as a spool.

How many bobbins do you need?

This depends on the project you are working on. If you are working on a loom, you will need to calculate the number of bobbins required based on the size and complexity of your project.

What are bobbins very short answer?

Bobbins are spools used to hold thread or other materials used in sewing and weaving.

What happens if you run out of bobbin thread?

If you run out of bobbin thread while sewing, the thread will break and the needle will stop moving. You will need to replace the bobbin thread with a new one before continuing with your project.

Why do I need to thread a bobbin?

Threading a bobbin is necessary because it supplies the lower thread to the sewing machine needle. The bobbin thread is what forms the stitches on the underside of the fabric and provides support to the stitches on the top side. Without a correctly threaded bobbin, the stitches will be loose and the fabric may not hold together properly.

How many types of bobbins are there?

There are three main types of bobbins: hand-wound, shuttle, and pre-wound. Hand-wound bobbins are wound by hand and are used with manual sewing machines. Shuttle bobbins are used in shuttle-style sewing machines. Pre-wound bobbins are ready-to-use bobbins filled with a spool of thread