So, you’ve been using your sewing machine a lot and something just feels wrong. You can’t seem to get the right stitch and the thread keeps breaking. The problem could be your sewing machine needle – it might be dull!

How can you tell? Don’t worry. I’ve written this article to walk you through all the steps of determining if your needle is dull or not. It’s easier than you think, I promise!

Whether it’s helping your check if it’s time for a new one or taking the guesswork out of troubleshooting, this article will disclose how to tell if your sewing machine needle is dull when it comes to reading a needle’s signs of wear and tear.

Related Topic: How to replace sewing machine needle

Table of Contents

ToggleWhat is a Dull Needle?

A dull sewing machine needle is one that has become worn down over time and is no longer able to penetrate fabric properly. This can cause skipped stitches, uneven stitching, difficulty threading the machine, and fraying or snagging of the fabric.

A dull needle will also be unable to cut through multiple layers of fabric without pulling at them. It’s important to replace your needle regularly in order to ensure that your projects are successful and that you’re getting the best results possible.

How to Tell If Your Sewing Machine Needle is Dull: Signs

There are several signs that can indicate a dull sewing machine needle, some of them are:

- Your fabric is not feeding properly through the machine.

- The needle is skipping stitches or not creating a clean stitch line.

- You hear loud noises when the machine is sewing.

- Threads are breaking more often than usual while sewing.

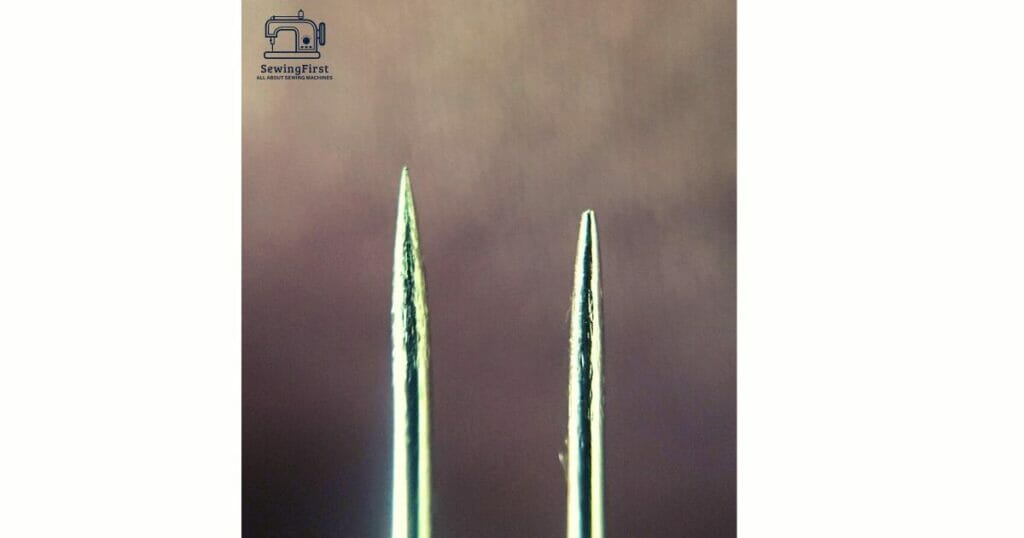

- You notice visible signs of wear on the needlepoint and eye of the needle.

How to Inspect Sewing Machine Needle?

Inspecting your sewing machine needle is an easy process. You’ll just need good lighting and a magnifying glass to be able to do it properly.

Using your magnifying glass, check the eye of the needle for any bends or nicks in the metal. If there are any defects, you need to replace the needle right away.

Also, grab the tip of the needle between two fingers and gently pull it to ensure that the needle is securely mounted into its shaft. If it feels loose, then it’s time for a new needle!

You should replace your sewing machine needle immediately if it shows any signs of damage or wear because otherwise, it will cause skips and improper stitches in thin fabric like silk and cotton. Not only that but it could create lackluster hemlines as well!

Finally, make sure to check the size of your needle. If it’s too small for the fabric you’re attempting to sew, then it won’t be able to penetrate the material properly and will cause skipped stitches or uneven stitching.

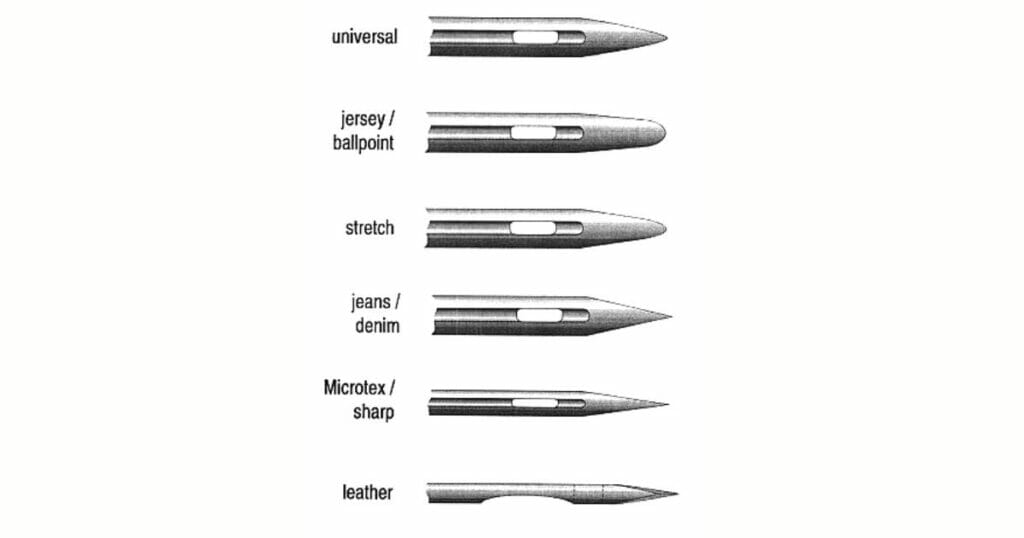

Different Types of Sewing Needles

Universal needles

These are the most common type of sewing machine needle and are suitable for a wide range of fabrics, including cotton, linen, silk, and wool.

They have a slightly rounded tip that helps them penetrate fabric without causing any damage. Universal needles come in various sizes ranging from 60/8 to 110/18.

Jeans needles

These are designed specifically for denim and other thick fabrics like canvas or leather. They have a sharp point that helps them penetrate through multiple layers of fabric without snagging or fraying the material. Jeans and needles come in sizes ranging from 70/10 to 90/14.

Ballpoint needles

These are designed for knit fabrics like jersey and interlock as they have a rounded tip that helps them slide between the fibers without damaging them. Ballpoint needles come in sizes ranging from 70/10 to 90/14.

Leather needles

These are designed specifically for leather and other heavy-duty materials like vinyl or suede. They have an extra-sharp point that helps them penetrate through thick layers of fabric without causing any damage. Leather needles come in sizes ranging from 80/12 to 110/18.

Microtex sharp needles

These types of needles are made with a very thin shaft to create precise details on lightweight fabrics like chiffon and organza. Leather needles have an extra sharp point for piercing through tougher fabrics, such as suede and canvas.

Betweens or quilting needles have a short shaft for quick stitching when piecing together patchwork quilts or stippling edges with decorative threading.

Stretch needles

This type of needle features a special eye and scarf that allows them to penetrate elasticated fabrics while minimizing skipped stitches or breakage of thread.

Different Sewing Machine Needle Sizes

When it comes to sewing machine needles, there are different sizes you need to know. The size of your needle depends on the type of fabric or thread you’re using.

The higher the number, the thicker the needle. If you’re working with thick fabrics, like denim or canvas, go for a larger size 10-16 needle. For finer materials like chiffon or organza choose a smaller size 9-11 needle.

When to Replace Your Sewing Machine Needle

- If you notice any bends or nicks in the metal, it’s time to replace your needle right away.

- If the tip of the needle feels loose when you pull it gently between two fingers, then it’s time for a new needle.

- If the size of your needle is too small for the fabric you’re attempting to sew, then it won’t be able to penetrate the material properly and will cause skipped stitches or uneven stitching.

- If you are sewing with elasticated fabrics, then it is important to use a special stretch needle that features an eye and scarf that allows them to penetrate while minimizing skipped stitches or breakage of thread.

- After every few projects, check your needle for signs of wear and tear and replace it if necessary – this will ensure that your sewing machine runs smoothly and produces quality results!

How Long Does a Sewing Machine Needle Last?

A good rule of thumb is about 8 hours of sewing in continuous use or 10-15 sewing projects. If you ever get a funny feeling like the needle is not going through the fabric smoothly, take the time to change it out.

Our advice? Err on the side of caution and replace your needles regularly! You’ll save yourself time and frustration by keeping a sharp eye out for dull needles and replacing them promptly.

How to Replace a Sewing Machine Needle

- Unplug your sewing machine and remove the needle using a screwdriver.

- Examine the needle for signs of dullness or breakage, such as bent points or burrs on the tip.

- Choose a replacement needle that is appropriate for your fabric type and project requirements.

- Slide the new needle into the needle clamp, ensuring it is facing in the correct direction (usually with the flat side of the shank towards the back of your machine).

- Secure it by tightening the screw with a screwdriver or other tool, being careful not to overtighten it.

- Re-thread your machine according to manufacturer instructions and test for proper stitching on a scrap piece of fabric before starting your project.

Conclusion

Knowing how to tell if your sewing machine needle is dull can save you from a lot of frustration and potential damage to your fabric and machine. Pay close attention to the threading process and look for signs of fraying or slipping threads.

Additionally, test piercing on either scrap fabric or paper with different settings on the tension dial knob in order to determine if it needs to be replaced. Doing so will ensure that you have the best sewing experience possible!

FAQs

How long will a sewing machine needle last?

A good rule of thumb is about 8 hours of sewing in continuous use or 10-15 sewing projects. If the needle is not going through the fabric smoothly, take the time to change it out.

How often should I replace my needle?

It is recommended to replace your needle after every 8 hours of sewing in continuous use or 10-15 sewing projects. This will ensure that your machine runs smoothly and produces quality results.

Can I sharpen sewing machine needles?

No, sewing machine needles cannot be sharpened. It is best to replace them with a new needle when they become dull.

How to make a needle blunt?

It is not possible to make a needle blunt. Needles become dull over time due to wear and tear from sewing. It is best to replace them with a new needle when they become dull.

How to fix a dull needle?

It is not possible to fix a dull needle. Needles become dull over time due to wear and tear from sewing. It is best to replace them with a new needle when they become dull.

Is it necessary to turn the power off when changing the sewing needle?

Yes, it is important to turn the power off when changing the sewing needle. This will help prevent any potential accidents or damage to the machine. Additionally, make sure that you unplug the machine from the wall before beginning any maintenance work.

What does a blunt needle look like?

A blunt needle will have a rounded point and may not be able to penetrate the fabric as easily as a sharp needle. Additionally, it may cause skipped stitches or fraying of the thread.

What will happen if you use the wrong needle in sewing machine?

Using the wrong needle in a sewing machine can cause damage to both the machine and the fabric. It can also lead to skipped stitches, fraying of the thread, and poor stitch quality. Therefore, it is important to use the correct needle for your project and machine.